In the manufacturing industry towards high precision, high flexibility and digital transformation of the background, measuring equipment not only to be accurate, but also “know how to adapt” to a variety of complex site. Portable Coordinate Measuring Machine?(CMM) has become an indispensable key tool in quality inspection, reverse engineering and rapid development process because of its flexibility, portability and high accuracy.

PMT, as a professional manufacturer of Portable Coordinate Measuring Machine (PCMM), is committed to providing technologically advanced, structurally optimized, and highly compatible portable CMM products to meet the diverse needs from industrial sites to education and research.

What is a multi-jointed arm measuring device?

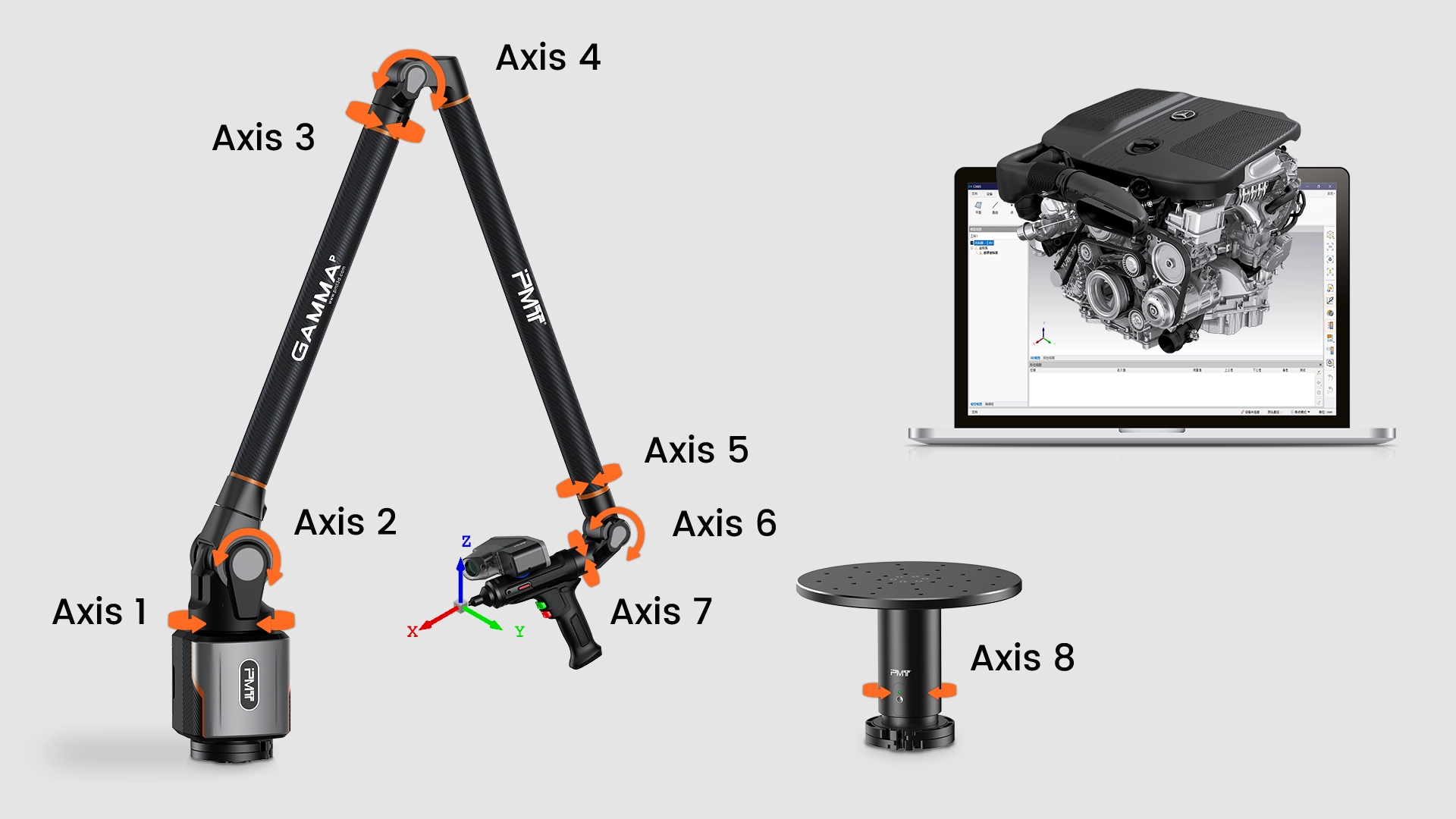

A multi-jointed arm measurement device resembles a flexible multi-axis industrial robot, the core of which calculates the 3D coordinates of a probe in space by means of a fixed arm length and real-time angular variations. The operator holds the probe in contact with the measurement point, or combines it with a laser scanning head for face-to-face data acquisition to obtain object geometry, GD&T parameters, and a high-density point cloud.

These devices are widely deployed in field application scenarios such as product quality inspection, mold dimensional control, workpiece digital modeling, and rapid prototype analysis.

PMT Product Series Overview

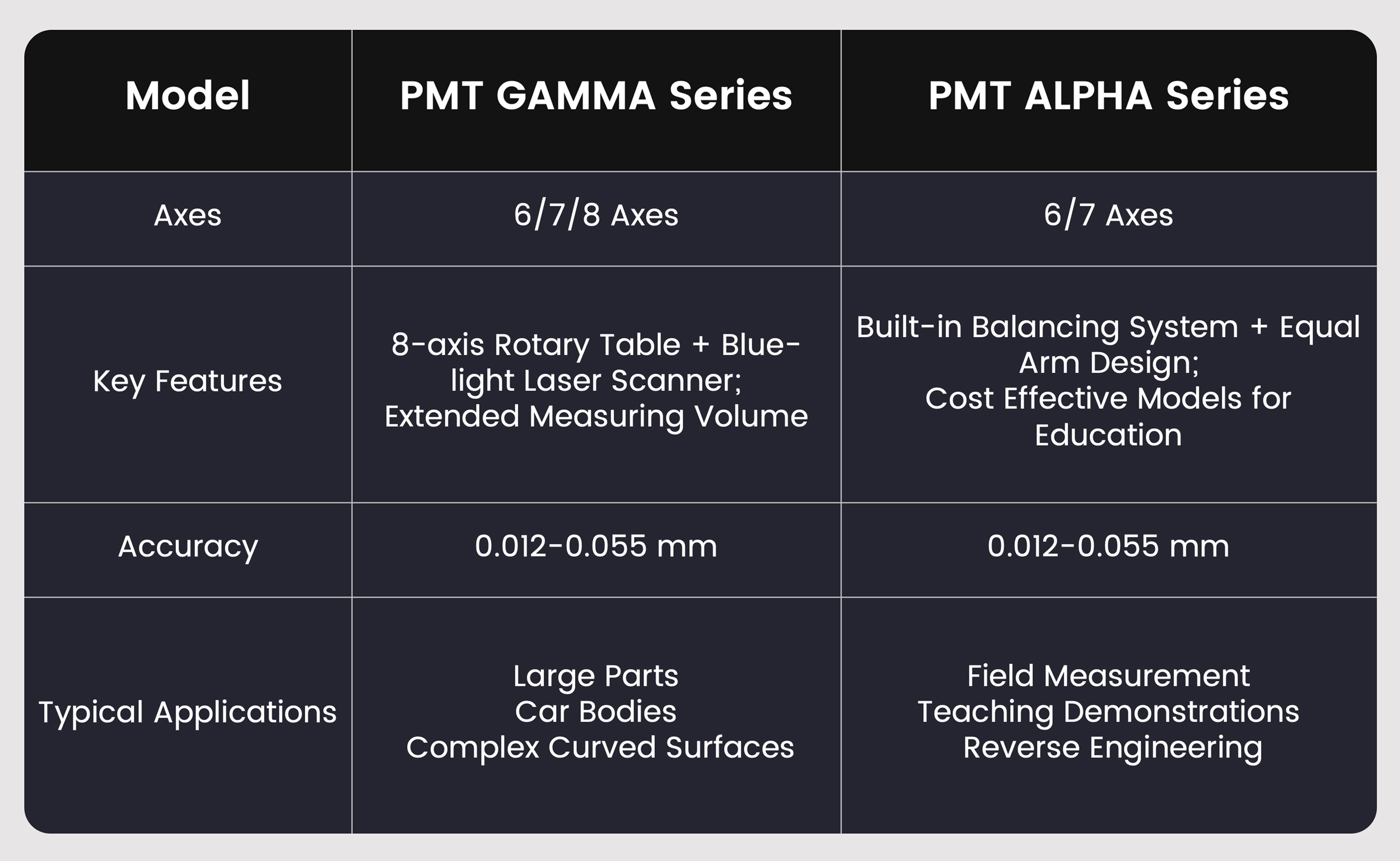

PMT offers two flagship series tailored to various professional needs:

Both series support dual-mode measurement (contact + laser scanning), making them ideal for a wide range of tasks in dynamic work environments.

Technical Advantages of PMT Measuring Arms

1. Technological Innovation

PMT employs a self-developed high-precision encoder system. Through external decoupling and internal balancing structural design, the equipment maintains high stability and measurement consistency even during multi-angle operation.

2. Materials and Manufacturing

The arm body is made from lightweight carbon fiber material, combining structural strength with portability. This allows single-handed operation and reduces operator fatigue during long-term use.

3. Functionality and Modularity

- Supports quick switching between contact and laser probes

- Integrated wireless Wi-Fi module enables cordless operation, ideal for large components or complex spatial environments

- Capable of rapidly outputting various result formats including GD&T parameters, STL models, and error analysis reports

Wide Range of Application Fields

Industrial Manufacturing and Assembly Inspection

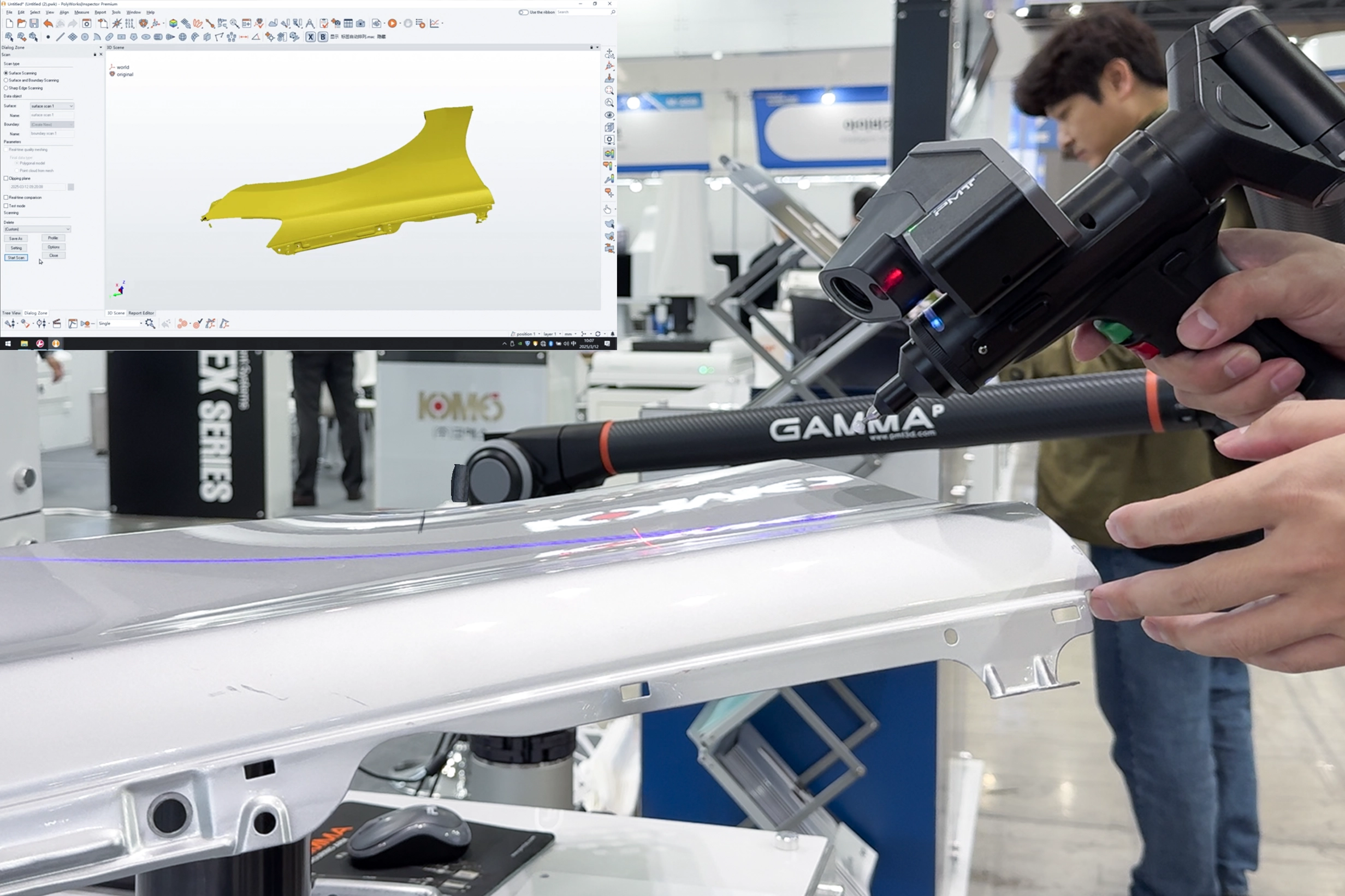

Applied in industries such as automotive manufacturing, aerospace, and machining for rapid inspection of complex parts. The GAMMA series is particularly suitable for large-scale components with extensive coverage and numerous measurement points.

Reverse Engineering and Digital Modeling

Combined with a laser scanning module, PMT measuring arms can quickly generate high-density point cloud data, enabling digital replication, modeling optimization, and re-design of legacy parts or handcrafted prototypes.

Education and Research

The ALPHA series offers excellent cost-performance, making it ideal for universities and vocational training institutions conducting coordinate measuring teaching and practical training, enhancing students’ engineering capabilities in digital manufacturing.

Compatible Software and Maintenance Support

PMT measuring systems are compatible with multiple professional measurement software platforms, covering the entire workflow from point cloud processing to reverse modeling:

- In-house software CAM3: Stable and intuitive, suitable for routine measurement and analysis

- Third-party platform compatibility:

- PolyWorks: Point cloud management and error analysis

- Geomagic: Reverse engineering and CAD modeling

- Metrologic: Fully automated inspection

- SpatialAnalyzer: Large-scale measurement solutions and coordinate system conversion

For maintenance, PMT recommends an annual factory-level calibration, with a standard calibration cycle of only three days, ensuring long-term accuracy and reliability.

Conclusion:

Multi-joint arm measuring devices are reshaping the way 3D measurement is conducted, thanks to their technical advantages of “flexible deployment + high-precision data acquisition.” PMT measuring arms not only meet demanding industrial inspection tasks but also offer cost-effective solutions for universities, laboratories, and product development teams.

Want to learn more? Contact us today!

As a professional manufacturer of portable coordinate measuring machines, PMT provides one-stop services including equipment selection, on-site training, and after-sales support. Whether you’re focused on high-precision inspection, reverse modeling, or improving on-site measurement efficiency, PMT will be your trusted partner.